Introduction

Optimizing FPC stackup configurations for enhanced performance is critical to designing high-speed printed circuit boards. By carefully selecting the materials, layer thicknesses, and trace geometries of the flexible printed circuit (FPC) stack up, engineers can significantly improve signal integrity, reduce crosstalk, and minimize electromagnetic interference. Through rigorous analysis and simulation, optimal configurations that meet the application’s specific performance requirements can be identified. Factors such as impedance control, insertion loss, and skew must be carefully considered to ensure reliable operation at high frequencies. By utilizing advanced design tools and techniques, engineers can achieve superior performance and reliability in FPC designs.

The significance of selecting the right FPC Stackup Material

Selecting the suitable FPC stackup material is crucial in ensuring the performance and reliability of a PCB. At JHDPCB, a one-stop PCB manufacturer, we understand the significance of using high-quality materials in all our projects. Whether a simple PCB or a complex PCB assembly, we leverage our expertise and strengths to deliver top-notch results. With a focus on quality and precision, we are committed to meeting the needs of our clients, no matter the volume or complexity of their projects. Visit our website at jhdpcb.com to learn more about our services and how we can help you achieve your PCB goals.

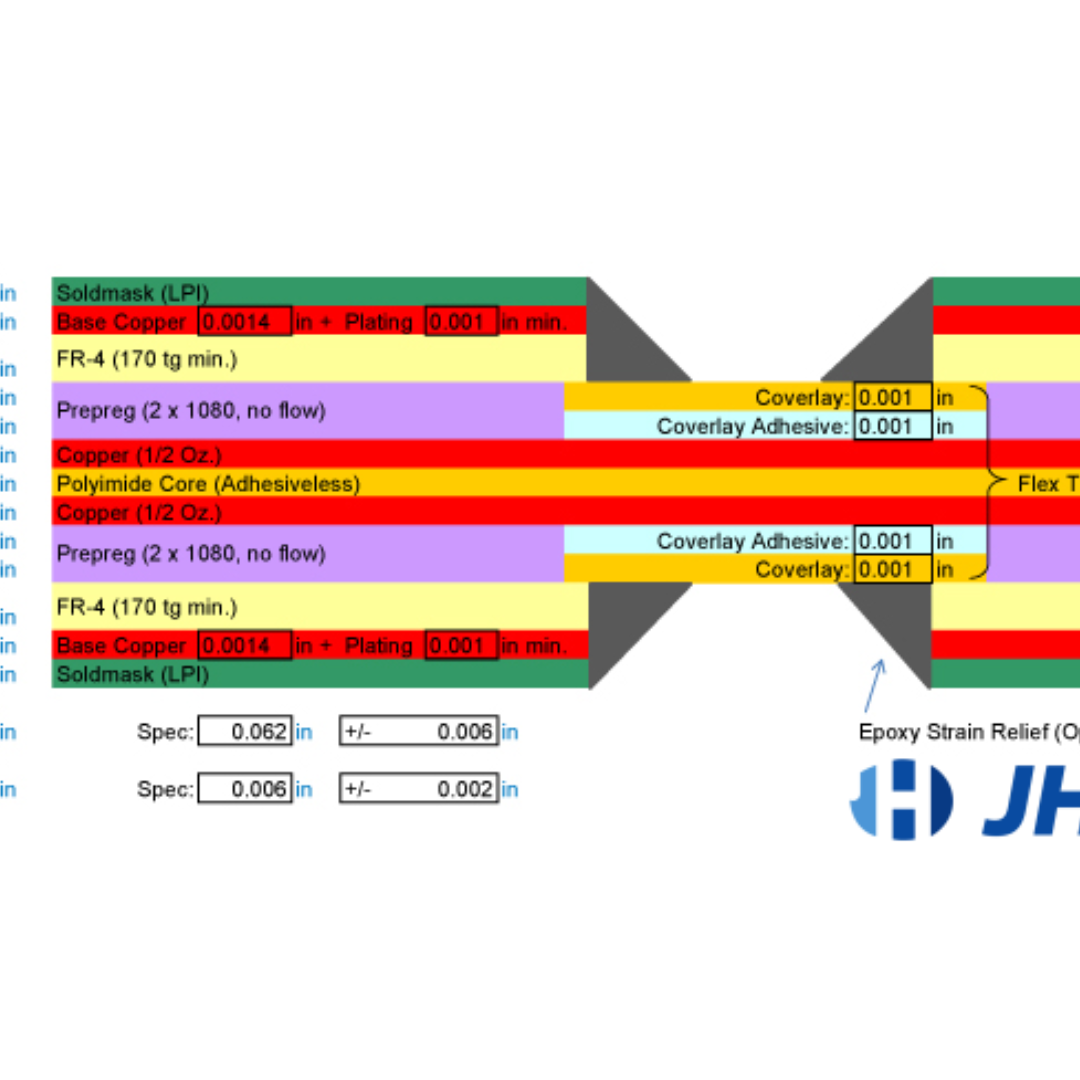

Importance of Proper Stackup in Rigid-Flex PCBs Stackup

Proper stackup design is crucial in rigid-flex PCBs to ensure the reliability and performance of the final product. At JHDPCB, a leading one-stop PCB manufacturer with over 15 years of rich experience, we understand the importance of a well-designed stackup. Our team of experts uses first-class precision equipment to provide customers with high-quality PCBs that meet their specific requirements. We recognize that every project is unique, so we offer customized solutions to ensure optimal performance and functionality. With our commitment to excellence and attention to detail, customers can trust us to deliver top-notch Rigid-Flex PCBs Stackup that exceed their expectations.

FPCB stiffeners type

FPCB stiffeners type-JHDPCB is a leading one-stop PCB manufacturer with over 15 years of rich experience in the industry. Our company prides itself on utilizing first-class precision equipment to provide customers with high-quality PCB solutions. We are dedicated to meeting the diverse needs of our clients by offering a wide range of PCB types, ensuring that we can accommodate any project requirements. Our team of skilled professionals is committed to delivering superior products and services, ensuring that every PCB we produce meets the highest standards of quality and reliability. Trust FPCB stiffeners type JHDPCB for all your PCB needs, and experience the difference our expertise and dedication can make in your projects. Contact us today for more details on our services.

Conclusion

The design and implementation of a well-optimized FPC stack-up configuration are significant in ensuring enhanced performance and reliability of electronic systems. Engineers can achieve superior functionality and efficiency in their PCB designs by meticulously considering factors such as signal integrity, impedance control, and thermal management. The quest for optimal FPC stacks can be realized through the application of advanced simulation tools and industry best practices, paving the way for cutting-edge technological innovations and seamless integration in electronic manufacturing.