Craftsmen have used molds for centuries to produce everything from Bronze Age weapons to contemporary consumer products. Early molds were typically made of stone, but thanks to technology, far more workable materials have emerged, such silicone.

Today, silicone molding is utilized in a multitude of industries. Product designers, engineers, do-it-yourself crafters, and even chefs use silicone molds to produce one-off or limited-edition parts.

Why Are Silicone Molds Required?

Due to its various benefits, silicone makes a great material for mold-making. Making custom designs is easy with silicone molding.

The molds are reasonably durable, so you can use them regularly without worrying that they’ll break.

Silicone is far more resistant to heat and cold, chemical exposure, and even fungus than rubber because of its inorganic makeup. Some benefits of silicone molds include the ones listed below:

Flexibility

Silicone is a flexible material that is easy to work with. Compared to harder materials like plastic, silicone is more pliable, lighter, and easier to remove once a part is fully created.

Due of silicone’s high degree of elasticity, both the mold and the final product are less likely to break or chip.

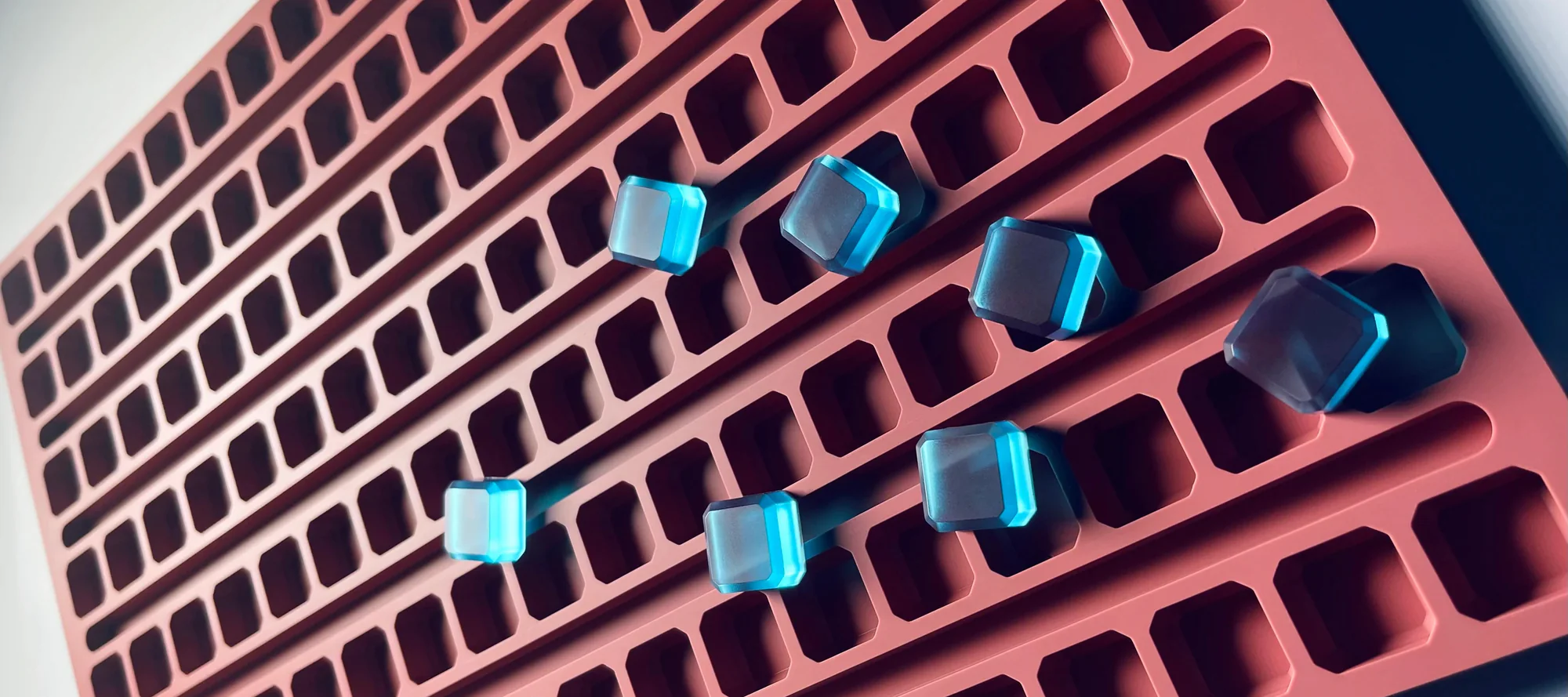

Custom silicone molds can be used to make everything from complex technical parts to confections or ice cubes with holiday themes.

Stability

Silicone can withstand temperatures between -65 and 400 degrees Celsius. There is also the possibility of a 700% elongation, depending on the formulation.

Since they can be baked, frozen, and stretched while being removed, silicone molds are extremely stable in a variety of conditions.

Durability

A silicone weed molds will typically make a number of runs. But it’s important to keep in mind that molds have a wide range of life spans.

The more regularly you cast, the more intricately detailed your design, and the quicker your mold deteriorates. Your silicone molds will last longer if you clean them with mild soap and water, let them dry fully, and keep them flat rather than stacked.

Limitations

While working with silicone has many benefits, there are a few downsides to be aware of:

In comparison to latex and organic rubbers, silicone is more expensive. A short check on Amazon reveals that silicone frequently costs over $100, or almost twice as much as latex.

Despite being flexible, silicone can break if stretched too far. Silicones are not all made equal. Always get silicone and other industrial supplies from a reputable supplier.

Common Uses for Silicone Molds

Due to their versatility and simplicity of usage, silicone molds are favored by both professionals and hobbyists.

The following are some examples of businesses and uses for silicone molds in product development:

Prototyping

Many different sectors use silicone molding for product development and prototyping.

Silicone molds are perfect for prototyping product designs as well as producing beta units for evaluating the market and consumer response to a new product because they are substantially less expensive than hard tooling for conventional manufacturing procedures, such as injection molding.

While urethane casting and silicone molding can work well for short runs of parts, 3D printing is better suited to swiftly generating one-off parts.

Jewelers can avoid the time-consuming task of carving wax patterns for each new piece while still casting from wax by using custom silicone molds to duplicate hand-carved or 3D printed designs in wax.

Due to this huge improvement in serial production, investment casting can now be done on a large scale.

Because silicone molds can capture such fine detail, jewelers may produce items with elaborate embellishments and complex geometries.

Consumer Goods Creators use silicone molds to produce a variety of custom crafts, like candles and soaps. Manufacturers of school supplies regularly employ silicone molds to produce products like chalk and erasers.

Food and beverage

Food-grade silicone molds are employed to produce a wide range of bizarre confections, such as lollipops, ice pops, and chocolates.

Due to silicone’s ability to endure temperatures of up to 400° Celsius, molds can also be used in the kitchen. Small baked goods like muffins and cupcakes work well in silicone molds.

Home Improvement Projects

Silicone molding is frequently used by independent artists and do-it-yourselfers to produce one-of-a-kind goods.

Using silicone molds, anything may be created, from dog treats to bath bombs—the possibilities are virtually endless.

Kids can enjoy the relaxing silicone molding hobby of creating a life cast of their hand. Use only silicone that is safe for your skin, please.

How to Make Patterns for Silicone Molding

The element utilized to produce an exact negative in your silicone mold is a pattern, which is also referred to as a master.

The use of that object as your pattern can make sense if all you’re trying to do is duplicate an existing item. Just make sure it can withstand the molding process.

Before creating a new design or prototype, you must first create your pattern; there are many ways to do this. A few techniques for making silicone molding patterns are listed below:

- Sculpting: You can create a pattern out of clay if you’re an experienced sculptor or working on a straightforward design. Kids will enjoy pattern sculpting as well, and DIYers may do it for little expense. Your pattern can be carved out of wood. Tiles and flat designs are best created with carved wood masters.

3D printing: To generate patterns, many professionals and professional designers turn to 3D printing. Desktop 3D printers have numerous advantages, such as design flexibility inside CAD software, high accuracy, ease of prototype change, and short turnaround times.