Introduction:

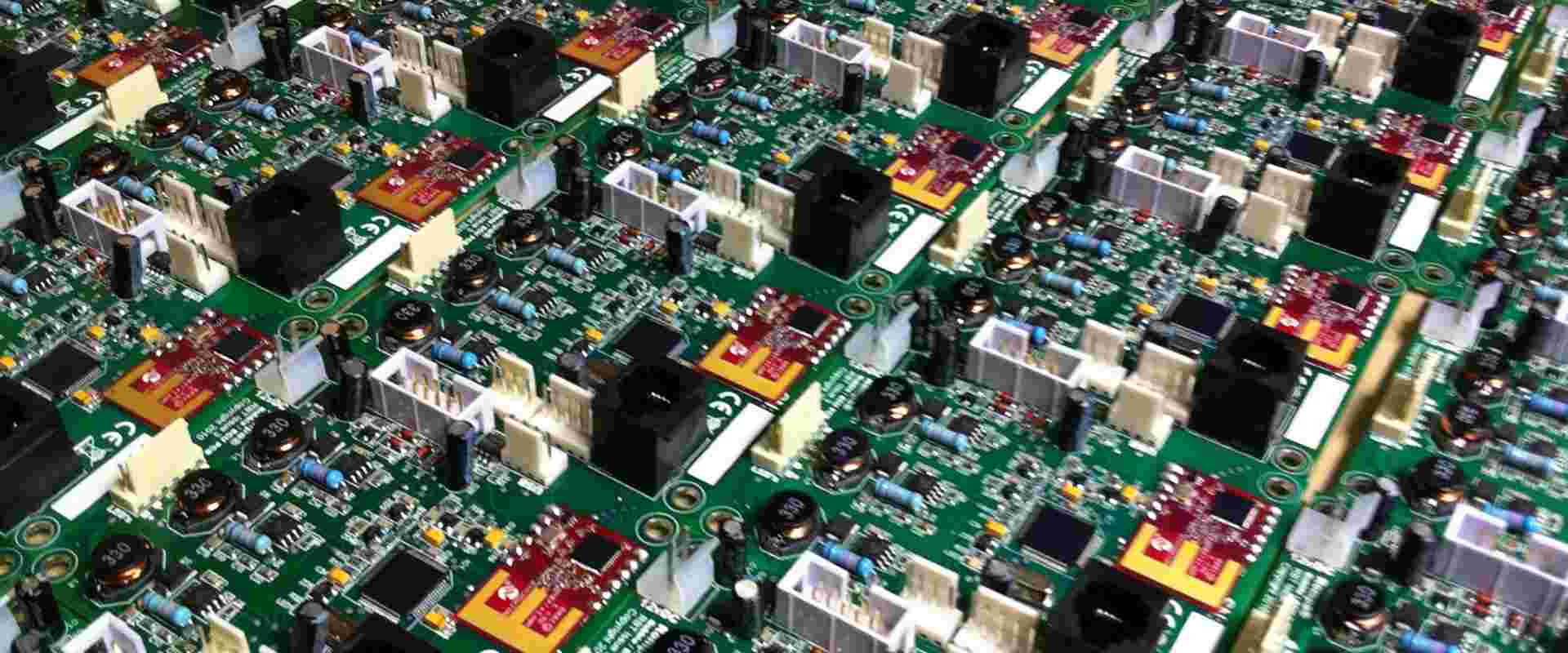

JHDPCB is a renowned name in the printed circuit board (PCB) industry, offering exceptional quality and reliability in their FR4 PCB manufacturing. FR4 is a widely used material in PCB production due to its excellent electrical properties, mechanical strength, and flame retardancy. JHDPCB’s commitment to delivering superior FR4 PCBs has made them a trusted choice among various industries. In this article, we will explore the key aspects of JHDPCB’s FR4 PCB production, highlighting their dedication to quality and innovation.

Unmatched Expertise in FR4 PCB Manufacturing:

JHDPCB boasts a team of highly skilled professionals with extensive experience in FR4 PCB manufacturing. Their technicians and engineers are well-versed in the latest industry standards and have a deep understanding of FR4 material properties. This expertise allows JHDPCB to produce FR4 PCBs that meet the most demanding requirements of various applications.

Cutting-Edge Technology and Equipment:

To ensure the highest quality standards, JHDPCB employs cutting-edge technology and state-of-the-art equipment in their production processes. They have invested in advanced machinery for every stage of PCB manufacturing, including precise drilling, etching, plating, and final inspection. By leveraging these modern facilities, JHDPCB can achieve exceptional accuracy, reliability, and consistency in FR4 PCB production.

Strict Quality Control Measures:

JHDPCB’s commitment to superior FR4 PCB production is evident in their rigorous quality control measures. At every stage of the manufacturing process, stringent inspections and tests are conducted to ensure adherence to the highest standards. The company follows internationally recognized quality management systems, such as ISO 9001 and UL certifications, to guarantee that their FR4 PCBs meet or exceed customer expectations.

Customization and Flexibility:

JHDPCB understands that every customer has unique requirements for their FR4 PCBs. To cater to diverse needs, they offer a wide range of customization options. From specific board dimensions and layer counts to surface finishes and solder masks, JHDPCB provides flexible solutions tailored to the customer’s specifications. This level of customization ensures that their FR4 PCBs seamlessly integrate into various applications, including automotive, aerospace, telecommunications, and more.

PCB ink

When it comes to manufacturing circuit boards, the selection of the right PCB ink is crucial. PCB inks play a vital role in ensuring efficient and reliable electronic connections. With a wide range of options available, understanding the different types and properties of PCB ink is essential.

Emphasis on Environmental Sustainability:

In addition to their commitment to quality, JHDPCB places great importance on environmental sustainability in their FR4 PCB production. They adhere to strict environmental regulations and follow eco-friendly practices throughout their manufacturing processes. JHDPCB promotes responsible waste management, energy conservation, and the use of green materials, ensuring minimal impact on the environment.

Conclusion:

JHDPCB’s dedication to superior FR4 PCB production has established them as a leading manufacturer in the industry. With their unmatched expertise, cutting-edge technology, strict quality control measures, and commitment to environmental sustainability, JHDPCB consistently delivers high-quality FR4 PCBs that meet the diverse needs of their customers. Whether for complex industrial applications or consumer electronics, JHDPCB stands as a reliable partner for top-notch FR4 PCBs. For more information about JHDPCB’s FR4 PCB production, please visit their website and explore their comprehensive range of services and capabilities.