CNC machinery is a new technology of great value and performs similar tasks to laser cutting. It can easily cut the materials into sharp vertical lines, just like laser cutting. Hence business owners get confused about the fact that what is the difference between laser cutting and CNC machinery for sale and which one you should use for your business. Further on in this blog post, we will discuss the difference between both of these methods to solve such confusion.

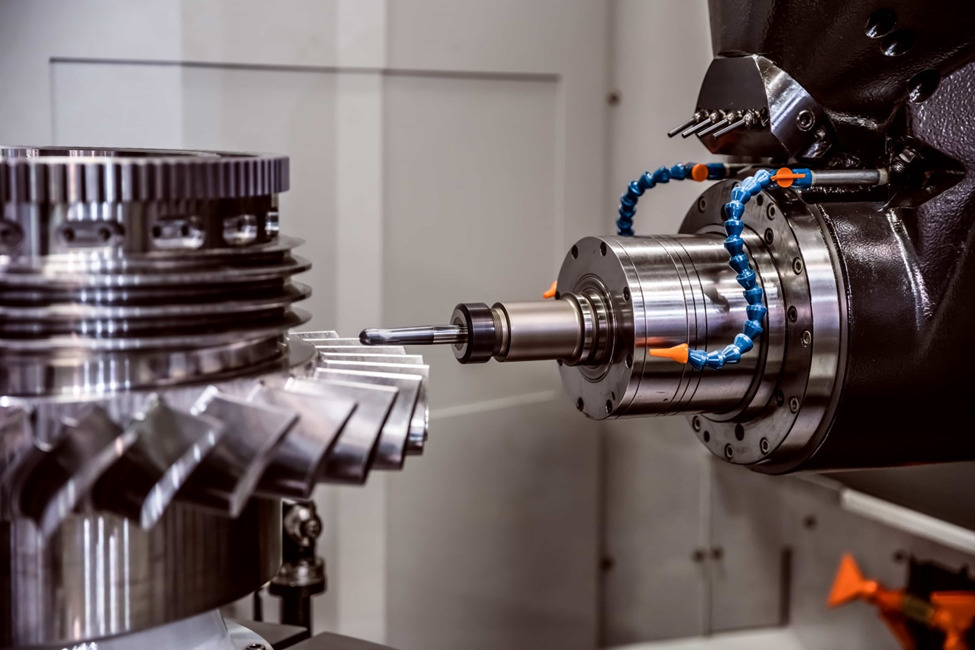

CNC machinery for sale allows 3D manufacturing:

The greatest difference between laser cutting and cutting through CNC machinery is that it allows 3D cuttings of the objects. Most CNC routers have 3-axis control, which enables them to cut quite complex and detailed designs. These designs are becoming quite popular for sign making, mold making, and many other daily applications. That allows the machinery to have great control and depth over the materials. Laser cutting, on the other hand, laser cutting does not cut materials in 3D. It can only cut parts two-dimensionally. Though through some easy techniques, you can make 3D designs out of the laser cutting but doing the complex one might get a bit difficult.

Laser cutting is only used for thin materials:

Laser cutting may be precise and provide sharp edges. Still, when compared to CNC machinery for sale, the downfall of it is that the laser is only used for cutting thin materials and does not work perfectly if there is a thick material that needs to be molded. It does not have much control over the depth compared to the CNC. The laser can cut materials like wood, plastic, paper, cork, etc. However, it has a maximum thickness through which it can be cut. For instance, the maximum thickness of a 1000W fiber laser cutting machine for carbon steel is about 10mm, for stainless steel is about 5mm, for aluminum plate is 3mm, and similar is for the copper plate.

Read more:- Some of the Most Popular Web Development Services | TheCustomWebsites

Industrial machining tools do not discolor the material:

Laser cutting is popular for discoloring certain materials like polystyrene foam. If this material is cut with fire, there are chances of it catching fire most of the time. Other than that, it leaves burned edges on the materials that are cut with it and has an increased chance of discoloring the different materials because of them catching fire. If the material catches fire or gets discolored even slightly, the whole of it goes to waste. That is not the case with industrial machining tools. There are no chances of the materials that are cut with it to catch fire or even get discolored the slightest bit.

Laser cutting of wood only has two depths:

Another downside of laser cutting wood is that it only has the option of two depths, one in which you can engrave and the other in which you can cut all the way through it. There is no in-between, and keeping in mind that only the thin layers of wood can be cut with the help of it. One can not create multi-depth cuts despite just stacking the layers on top of each other after the laser has cut them.

After reading this, hopefully, you will be able to understand and decide accordingly which machinery you want for your business. If you decide on buying a CNC machinery, we recommend Flint Machine. They have a huge range and will provide you with a machine at a very reasonable cost.

Our next section comprises commonly asked questions that will give you more information about CNC machinery for sale.

Commonly Asked Questions:

What is laser cutting used for?

Laser cutting is used for cutting different materials, making shapes and designs into woods, steel, aluminum, etc., for making parts that will be used in the manufacturing industry. It has widely being used in this industry for quite sometime now, and now it is also making its name amongst other sects such as schools and hobbyists.

How do you use a laser cutting machine?

A laser cutting machine is used by directing a very powerful laser beam at a precise focal length on the material that is either cut or etched. It all depends upon how the laser cut has been set up. Laser cutting is quite similar to the other tools. The only difference is that it uses a laser.

What are the limitations of laser cutting?

Though laser cutting is beneficial, there are some limitations to it, too. That is, it cannot cut through thicker objects. It can also cause the materials to burn, which can cause a fire and discoloration of the material and release hazardous fumes.

Can CNC do 3D?

Yes, CNC can do 3D. It has a 3-axis control, which enables it to cut detailed and complex designs. It is becoming popular in sign making, mold making, and many more.